ALTAKHLEEQ ELECTRO MECHANICAL Industries – Dubai

Ducts are available mainly in two types Rectangular and Circular ducts but can be made of different material like G.I Mild steel, Stainless steel and aluminum. Installing Duck work has many advantages like reducing electricity bills by correct channeling and sizing according to the airflow but this can be achieved only with good quality ducts and qualified installation technicians.

Duct Manufacturing & Production Process

- After receiving the tagged drawing a fabrication schedule is prepared for the ducts to be made after coordinating with the customer

- The fabricator receives the fabrication schedule and dimensions of the duct to be manufactured

- CNC Operator inputs the data into the CNC machine such as coil line or Plasma cutter

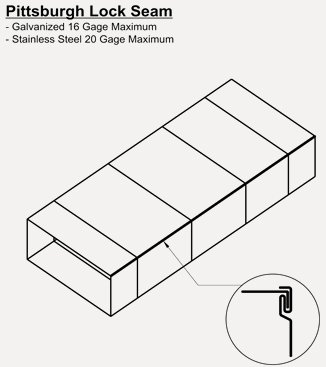

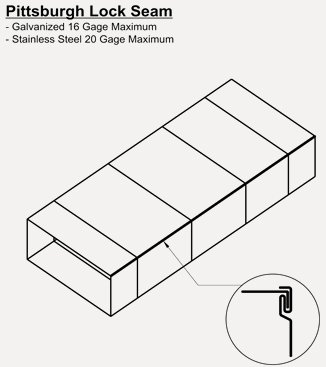

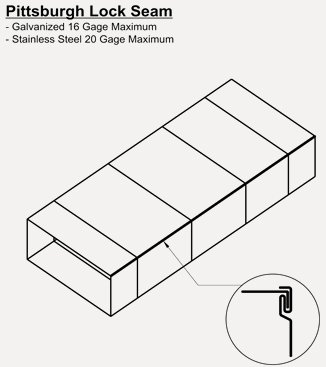

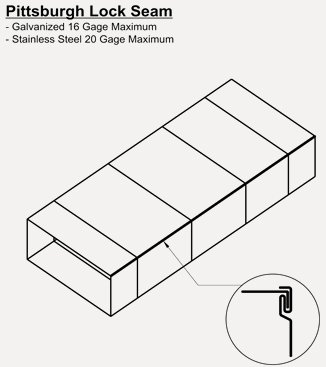

- The square ducts are processed through the CNC operated Coil Line machine to make ducts of 1200mm (standard length). This duct is then passed through the duct zipper for seam joining and Automatic Precision Cleat bending machine for “C” cleats to form complete duct. At each stage, a factory foreman is continuously monitoring the quality. After completion these ducts are sent to quality inspection by Quality Assurance Department.